inspirational-25

Comments

-

There's no doubt i would fully rate it after i read what is the idea about this article. You did a nice job.

OKBet philippines -

Get a chance to win the prizes!!! Want to know more about the site? visit here --->> OKBet super jackpot promo

-

รวมเกมสล็อตสนุกๆ ไว้ในเว็บเดียวที่นี่PGSLOTล็อกอินเพื่อเข้าเล่นได้ที่หน้าเว็บไซต์ระบบอัตโนมัติที่ให้ความเสถียรและทันสมัยกดรับสิทธิพิเศษก่อนใครเพียงสมัครสมาชิกลุ้นรับรางวัลจากเกมได้เร็วที่สุดลงเดิมพันได้ไม่จำกัดเวลาลุ้นรับรางวัลง่ายที่สุด

-

Наша бригада опытных исполнителей предоставлена подать вам перспективные подходы, которые не только подарят прочную охрану от холодильности, но и подарят вашему дому трендовый вид.

Мы занимаемся с последовательными материалами, ассигнуруя долгий срок использования и отличные результирующие показатели. Изолирование внешнего слоя – это не только сбережение на подогреве, но и забота о экологии. Спасательные инновации, какие мы осуществляем, способствуют не только дому, но и сохранению природных ресурсов.

Самое основополагающее: Сколько стоит сделать фасад дома с утеплением у нас начинается всего от 1250 рублей за кв. м.! Это доступное решение, которое превратит ваш домик в подлинный теплый уголок с минимальными затратами.

Наши работы – это не всего лишь изолирование, это составление пространства, в котором каждый элемент символизирует ваш личный манеру. Мы возьмем во внимание все твои требования, чтобы сделать ваш дом еще еще больше дружелюбным и привлекательным.

Подробнее на http://www.ppu-prof.ru

Не откладывайте труды о своем ларце на потом! Обращайтесь к квалифицированным работникам, и мы сделаем ваш дом не только теплым, но и по последней моде. Заинтересовались? Подробнее о наших проектах вы можете узнать на сайте компании. Добро пожаловать в обитель благополучия и стандартов. -

Наша команда искусных исполнителей готова предложить вам актуальные методы, которые не только обеспечивают надежную защиту от прохлады, но и преподнесут вашему жилищу модный вид.

Мы занимаемся с современными материалами, подтверждая продолжительный срок использования и отличные итоги. Теплоизоляция облицовки – это не только сокращение расходов на тепле, но и заботливость о экологической обстановке. Энергоспасающие методы, какие мы внедряем, способствуют не только дому, но и поддержанию природных богатств.

Самое центральное: Услуги по утеплению фасадов у нас стартует всего от 1250 рублей за м2! Это доступное решение, которое преобразит ваш дом в фактический уютный район с минимальными затратами.

Наши пособия – это не просто изолирование, это создание территории, в где любой элемент показывает ваш личный манеру. Мы примем во внимание все ваши требования, чтобы переделать ваш дом еще еще более комфортным и привлекательным.

Подробнее на http://ppu-prof.ru

Не откладывайте дела о своем ларце на потом! Обращайтесь к профессионалам, и мы сделаем ваш помещение не только теплым, но и стильнее. Заинтересовались? Подробнее о наших услугах вы можете узнать на официальном сайте. Добро пожаловать в сферу удобства и высоких стандартов. -

Наша группа опытных специалистов завершена предъявить вам инновационные приемы, которые не только гарантируют устойчивую покров от холодных воздействий, но и подарят вашему домашнему пространству изысканный вид.

Мы трудимся с новейшими средствами, ассигнуруя долгосрочный термин эксплуатации и выдающиеся результирующие показатели. Изолирование наружных стен – это не только сокращение расходов на прогреве, но и ухаживание о экосистеме. Сберегательные технологии, какие мы применяем, способствуют не только твоему, но и сохранению природы.

Самое важное: Средняя цена утепления фасада у нас стартует всего от 1250 рублей за метр квадратный! Это доступное решение, которое превратит ваш помещение в настоящий тепловой корнер с минимальными тратами.

Наши произведения – это не единственно утепление, это разработка пространства, в где каждый элемент символизирует ваш персональный образ действия. Мы рассмотрим все ваши желания, чтобы сделать ваш дом еще больше приятным и привлекательным.

Подробнее на https://www.ppu-prof.ru

Не откладывайте труды о своем обители на потом! Обращайтесь к квалифицированным работникам, и мы сделаем ваш домик не только согретым, но и по последней моде. Заинтересовались? Подробнее о наших делах вы можете узнать на нашем сайте. Добро пожаловать в пространство уюта и качества. -

В ассортименте нашего интернет-магазина сантехники представлена только оригинальная продукция таких известных брендов как Джилекс, PRO AQUA, Valfex, LD, СТМ и многих других

-

Простые и эффективные способы выведения недвижимости из залога и урегулирования обременений для защиты ваших прав и интересов без лишних трат и напряжения

Владение недвижимостью всегда сопровождается риском, который может стать невыносимым, особенно в условиях непредвиденных обстоятельств. Быть закладнам - это значительно ограничивает возможности владельца: так, например, как мы ранее упоминали, это может стать причиной попадания недвижимости под действие продолжительных изъятий, а зачастую даже последующей продажи. Однако существует несколько способов освободить недвижимость от обременения, при этом сохраняя ее ценность и достигая своих целей.

Одним из таких способов является доверительное управление имуществом, которое предоставляет гарантированную возможность избавиться от обременения недвижимостью, не теряя ее собственности. Это - эффективный и грамотный инструмент, позволяющий остаться независимым от кредитного учреждения и освободить свое имущество от залога, путем передачи его на временное управление квалифицированному управляющему лицу - доверительному управляющему.

Итак, доверительное управление имуществом дает вам возможность полностью освободить свое имущество от попавшей в залог недвижимости, предлагая вам финансовую свободу и защиту от преждевременной продажи. Другими словами, это инструмент, позволяющий вам сохранить собственность на недвижимость, но при этом нести ответственность только за управление и включая риск утраты ценности вложенного капитала.

Подобрали для вас полезные статьи про недвижимость, такие какие покупка недвижимости -

Электронная регистрация в Росреестре - Сделки онлайн - Центр "Недвижимость и право"

Электронная регистрация в Росреестре сделок с недвижимостью. Ускоренные сроки - 3-7 дней. Выписки из ЕГРН. -

Рекомендации выбора и покупки текстильных обоев для создания стильного и уютного интерьера вашего дома

Интерьер – это визитная карточка дома, которая отражает вкус и индивидуальность его владельцев. Поэтому так важно выбрать правильное оформление, которое создаст уютную атмосферу и подчеркнет ваш стиль. Одним из наиболее интересных решений в дизайне помещений сегодня стали текстильные обои.

Понятие «текстильные обои» охватывает широкий спектр разнообразных материалов и фактур. Это мягкие, приятные на ощупь изделия, созданные из натуральных или синтетических волокон. Их назначение – не только украсить стены, но и подчеркнуть их важность в создании уютной атмосферы в помещении.

Своей привлекательностью текстильные обои обязаны не только оригинальной текстуре, но и возможности варьировать цветами и узорами. Они помогут создать уникальный стиль вашего интерьера, быть ключевым элементом в оформлении или органично дополнить уже существующие композиции.

Мы предлагаем для вас скидку 5% на наши дизайнерские обои -

Лучшие онлайн казино ТОП игровые автоматы Рейтинг 10 лучших онлайн-казино от TOP CASINO

Получите приветственный бонус 250 Бесплатных спинов + 395% к депозиту для Volna от нашего ресурса TOP CASINO -

Хотите жить в современной квартире в Новосибирске?

Наша компания предлагает широкий выбор квартир в новостройках различных жилых комплексов, которые полностью соответствуют самым высоким стандартам качества.

Мы также поможем в получении ипотечного решения, чтобы сделать процесс покупки квартиры максимально удобным для вас.

Ваша персональная скидка - 10% -

На нашем сайте вы найдете самую полезную информацию о недвижимости.

Ознакомьтесь с такими темами, как продажа жилья и закон о собственности.

Мы поможем вам принять осознанное решение при покупке или продаже недвижимости! -

Хотите узнать всё о процессе регистрации квартиры в собственность?

Наш портал предлагает вам самые полезные информационные статьи на такие темы, как: оформление квартиры в МФЦ, покупка квартиры от застройщика.

Здесь вы найдете ответы на все ваши вопросы и получите подробную информацию о процессе оформления жилья -

На нашем портале вы найдете любую информацию о покупке недвижимости - от покупки квартиры до бронирования жилья.

Доверьтесь профессионалам и сделайте правильный выбор с нами!

Ваша индивидуальная скидка на консультацию 5% -

Хотите, чтобы квартира в новостройке стала вашим уютным домом?

Мы знаем, как сделать это быстро и без лишних хлопот! На нашем портале мы поделимся с вами секретами ремонта новостроек без отделки. Узнайте, как создать интерьер своей мечты, сделав перепланировку квартиры с минимумом затрат и максимумом комфорта. Пусть ваша квартира отражает ваш вкус и стиль!

Специальная скидка для вас – 20%! -

Хотите купить квартиру с черновой отделкой, но не знаете, с чего начать?

Мы подготовили для вас полезные советы по покупке жилья от застройщика и многим другим важным моментам.

Узнайте, как нужно подготовиться к покупке квартиры с отделкой и избежать неприятных сюрпризов в будущем. Наша статья поможет вам сделать правильный выбор и сэкономить время и деньги. -

Добро пожаловать на наш портал, где вы найдете множество полезных статей на такие темы, как прием квартиры в новостройке и проверка квартиры.

Узнайте больше о том, как купить квартиру на стадии котлована. Мы поможем вам стать уверенным покупателем и избежать возможных проблем в будущем! -

На нашем ресурсе вы найдете много полезных статей на такие темы, как: отделка новой квартиры и ремонт новой квартиры.

Узнайте, как выбрать стиль интерьера при евроремонте в новостройке!

Мы подскажем вам оптимальные решения и поделимся секретами красивого дизайна и ремонта.

Также мы дарим вам личную скидку на консультацию – 15%! -

Читайте полезные статьи на важные темы, связанные с недвижимостью, например покупка квартиры в новостройке или покупка недвижимости.

-

На нашем сайте вы найдете самую полезную информацию о ценах на квартиру, а также о коммерческой недвижимости.

Мы предлагаем актуальные статьи, которые помогут вам принимать правильные решения и сохранить ваш бюджет! -

Хотите стать счастливым обладателем собственной недвижимости, но не знаете, с чего начать?

Наш портал предлагает вам полную информацию на такие темы, как ремонт в новостройке или договор дарения недвижимости

Посетите наш сайт и начните свой путь к новому жилью уже сегодня! -

Добро пожаловать на наш сайт о недвижимости!

Здесь вы найдете информационные статьи на такие темы, как обременение на недвижимость или покупка недвижимости.

Мы расскажем вам о тонкостях покупки квартиры в новостройке и поделимся секретами успешного ремонта в новостройке.

Будьте в курсе всех актуальных новостей и разберитесь во всех вопросах рынка недвижимости вместе с нами! -

Читайте полезные статьи на важные темы, связанные с недвижимостью, например покупка квартиры в новостройке или налог на дарение недвижимости.

-

Хотите стать счастливым обладателем собственного жилья, но не знаете, с чего начать?

Наш сайт предлагает вам полную информацию на такие темы, как налог на продажу недвижимости или покупка квартиры в новостройке. -

На нашем ресурсе вы найдете самую важную информацию о покупке квартиры в новостройке, а также о возврате НДФЛ за недвижимость.

Мы предлагаем экспертные советы, которые помогут вам принимать правильные решения и сохранить ваш бюджет! -

Читайте интересные статьи на актуальные темы, связанные с недвижимостью, например отделка квартиры с нуля или продажа недвижимости.

Не откладывайте свою мечту о собственном жилье на потом. Посетите наш сайт и начните свой путь к новому дому уже сегодня! -

Хотите быть в курсе всех актуальных тенденций на рынке недвижимости? На нашем портале вы найдете полезные статьи на такие темы, как коммерческая недвижимость, а также прописка в новостройке.

Узнавайте первыми о самых выгодных предложениях и важных советах от профессионалов! -

На нашем сайте вы найдете много полезных статей на следующие темы: продажа недвижимости и налоговые льготы.

-

Добро пожаловать на наш интернет-ресурс, где вы найдете множество интересных статей на такие темы, как кадастровая стоимость и инвестиции в недвижимость.

-

Приглашаем на наш новый портал, где вы найдёте самые важные новости о рынке недвижимости!

Ознакомьтесь с такими темами, как продажа недвижимости, а также квартиры в новостройке. -

На нашем портале вы найдете полезные статьи, которые помогут вам разобраться во всех нюансах покупки недвижимости.

Вас ждут статьи на такие темы, как новостройка от застройщика, и многие другие! -

На нашем ресурсе вы найдете самую интересную информацию о агентствах недвижимости в Махачкале, а также о покупке квартиры в ЖК.

-

Читайте полезные статьи на важные темы, связанные с рынком невижимости, например кадастровые номера объектов или цены на недвижимость.

-

На нашем ресурсе вы можете прочитать статьи на такие темы, как налоги на недвижимость, а также инвестиции в недвижимость.

-

Читайте интересные статьи на важные темы, связанные с продажей жилья, например покупка квартиры в новостройке или стоимость недвижимости в Москве.

-

Добро пожаловать на новый портал о покупке и продаже жилья!

Вы можете ознакомиться с такими темами, как налог на недвижимость и федеральное агентство недвижимости. -

Добро пожаловать на новый сайт о покупке и продаже жилья!

Вы можете ознакомиться с такими темами, как дарственная на недвижимость и оценка недвижимости. -

Читайте интересные статьи на актуальные темы, связанные с продажей жилья, например недвижимое имущество, а также право собственности на квартиру в новостройке.

-

На нашем сайте вы найдете самую интересную информацию о недвижимости.

Ознакомьтесь с такими темами, как недвижимость у моря и квартиры в Новой Москве. -

Добро пожаловать на наш сайт о покупке и продаже жилья!

Вы можете ознакомиться с такими темами, как цены на недвижимость и аренда коммерческой недвижимости. -

Добро пожаловать на наш сайт о покупке и продаже жилья!

Вы можете ознакомиться с такими темами, как запрет на сделки с недвижимостью и брокерское агентство недвижимости. -

Наш ресурс предлагает вам самые актуальные статьи на такие темы, как покупка недвижимости, а также покупка квартиры в новостройке от застройщика.

Здесь вы найдете ответы на все вопросы и получите полную информацию о процессе регистрации жилья. -

Добро пожаловать на новый ресурс о покупке и продаже жилья!

Вы можете ознакомиться с такими темами, как кадастровая стоимость недвижимости и недвижимость в Краснодаре. -

Добро пожаловать на наш сайт о продаже недвижимости! Здесь вы найдете актуальные статьи, советы и новости о рынке недвижимости, юридических аспектах покупки и продажи недвижимого имущества, аренде коммерческих помещений, инвестициях в недвижимость и многом другом.

https://glavdecor-ekb.ru/ -

Хотите быть в курсе всех современных тенденций на рынке недвижимости? На нашем портале вы найдете полезные статьи о стоимости аренды квартир, ценах на жилье, ремонте в новостройках.

Узнавайте первыми о самых важных советах от экспертов, чтобы сделать правильный выбор и сэкономить свои деньги.

https://ucnedv.ru/ -

Узнайте все о покупке квартир в новостройках от надежного застройщика, расчетах налогов на недвижимость, получении кредитов под залог и налоговом вычете за покупку квартиры на нашем сайте!

Подробные и информативные статьи помогут вам разобраться во всех нюансах рынка недвижимости и сделать обоснованный выбор.

https://donskoy-alians.ru/ -

Псс... Хотите узнать о самых выгодных направлениях инвестирования в недвижимость, основных рисках и способах их минимизации? Сайт https://aibismach.ru

-

Всем привет! Интересные статьи о недвижимости. Аренда, купля/продажа, недвижимость как бизнес. Подробнее http://sma-repair.ru

-

Приветствую. Может кто знает, где почитать полезные статьи о недвижимости? Интересуют темы аренды и купли/продажи недвижимости. Пока нашла https://alfapromnn.ru

-

Добро пожаловать на наш ресурс о недвижимости!

Здесь вы найдете актуальные статьи и новости о рынке недвижимости, правовых аспектах покупки жилья, аренде коммерческих помещений, инвестициях в недвижимость и многом другом.

Мы рады поделиться с вами полезной информацией и помочь вам принимать осознанные решения в сфере покупки недвижимости. -

Добро пожаловать на новый ресурс о покупке и продаже жилья!

Ознакомьтесь с такими темами, как цены на недвижимость и аренда квартир. -

Откройте двери в мир недвижимости с нашим ресурсом!

Изучите экспертные статьи от специалистов в области недвижимости. Узнавайте о налогах на недвижимость, осуществляйте успешные сделки купли-продажи квартир, и всегда оставайтесь в курсе последних новостей рынка.

http://ufficioporta.ru -

Приветствую. Может кто знает, где найти разные блоги о недвижимости? Интересуют темы аренды и купли/продажи недвижимости. Сейчас читаю https://profmaster-vrn.ru

-

Заходите на информационный портал о недвижимости!

Здесь вы найдете полезные советы о аренде недвижимости, а также о ипотечном кредитовании.

Мы расскажем вам о тонкостях покупки вторичной квартиры и поделимся другими секретами. -

Хотите быть в курсе всех важных тем в мире недвижимости?

На нашем сайте вы сможете найти множество интересных статей о квартирах от застройщика, налогах на недвижимость, а также о анализе рынка недвижимости.

http://zoltor24sochi.ru -

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Интересуют темы аренды и купли/продажи недвижимости. Сейчас читаю https://iter21.ru

-

Заходите на наш ресурс, где вы найдете множество полезных статей на тему приемки квартиры в новостройке или покупки квартиры с черновой отделкой. Узнайте, как защитить себя от ненадёжных застройщиков, какие проверки осуществить перед покупкой жилья, и о многом другом!

http://citadel-ca.ru -

У нас вы найдете информационные статьи на тему недвижимости, например, отделка квартиры с нуля, оценка недвижимости, юридическое сопровождение сделки.

Узнайте все нюансы, которые помогут вам принять верное решение и осуществить успешную сделку с недвижимостью. Наши статьи помогут вам быть в курсе последних новостей и законов жилищного рынка, а также избежать ошибок.

http://domzenit.ru -

Читайте полезные статьи на важные темы, связанные с продажей жилья, например квартира от застройщика или стоимость недвижимости в Москве.

Сайт: http://ooo-trotuar.ru -

Хотите узнать всё о процессе регистрации квартиры?

Наш сайт предлагает вам самые актуальные статьи на такие темы, как: оформление квартиры в МФЦ, ипотечное кредитование.

Здесь вы найдете ответы на все вопросы и получите подробную информацию о процессе регистрации жилья в собственность. -

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://inter-garage.ru

-

Приветствую. Может кто знает, где найтиполезные статьи о недвижимости? Сейчас читаю https://savvys-rus.ru

-

Приветствую. Может кто знает, где почитатьразные блоги о недвижимости? Пока нашел https://optorgsib.ru

-

На нашем ресурсе вы найдете самую интересную информацию о покупке и продаже недвижимого имущества.

Ознакомьтесь с такими темами, как квартира в новостройке и налоговые вычеты на недвижимость.

Мы поможем вам принять осознанное решение при покупке или продаже жилья, а также предоставим важные новости о рынке недвижимости.

Удобный поиск, свежие объявления и информативные статьи - все это доступно у нас! -

Хотите быть в курсе всех значимых тем в мире недвижимости?

На нашем ресурсе вы найдете множество полезных статей о покупке и продаже жилья, а также о ипотеке на недвижимость.

Узнайте все, что вам необходимо для успешных сделок и принятия важных решений в сфере недвижимости.

https://prestizh-stroi.ru -

На нашем сайте вы найдете все необходимые сведения о недвижимости - от бронирования квартиры в новостройке до приобретения недвижимости от застройщика.

Мы поможем вам выбрать идеальную квартиру на вторичном рынке, расскажем, как не ошибиться при выборе жилья и подскажем, как сэкономить время и деньги.

Ждём в гости: https://quartz-rsk.ru -

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://jkstolitsa.ru

-

Хотите узнать всё о процессе получения права собственности на квартиру?

Наш портал предлагает вам самые полезные статьи на тему покупки и продажи недвижимости.

Здесь вы найдете ответы на все вопросы и получите полную информацию о процессе регистрации жилья.

https://krovlistroy.ru/ -

На нашем сайте вы найдете интересные статьи, которые помогут вам разобраться во всех нюансах продажи недвижимости.

Вас ждут материалы на такие темы, как ремонт в новостройке, дарение недвижимости, и многие другие! -

На нашем сайте вы найдете любую информацию о приобретении недвижимости - от покупки квартиры до бронирования жилья.

Доверьтесь экспертам и сделайте правильный выбор с нами! -

На нашем интернет-ресурсе вы найдете самую актуальную информацию о недвижимости в новостройках.

Ознакомьтесь с такими темами, как квартиры в новостройках и налоговые вычеты на недвижимость.

Мы поможем вам принять взвешенное решение при покупке или продаже жилья! -

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://master-architector.ru

-

На нашем сайте вы найдете самую полезную информацию о стоимости квартир, а также о коммерческой недвижимости.

Мы предлагаем актуальные статьи, которые помогут вам принимать правильные решения и сохранить ваши деньги! -

Добро пожаловать на наш сайт, где вы можете прочитать множество информационных статей на такие темы, как приемка квартиры в новостройке, и на многие другие.

Узнайте всё о том, как купить квартиру от застройщика. Мы поможем вам стать подкованным покупателем, и избежать различных проблем в будущем! -

Интересуетесь недвижимостью? Наш сайт - ваш надежный гид в этой сфере. У нас вы найдете множество актуальных статей на такие темы, как квартиры от застройщика, а также оценка недвижимости.

Подробные аналитические материалы, экспертные мнения и важные рекомендации — все это доступно у нас! -

Узнай все о недвижимости на одном ресурсе! Наши полезные статьи о квартирах от застройщика и о агентствах недвижимости помогут тебе разобраться во всех нюансах этой сложной сферы.

Не упусти возможность быть в курсе всех изменений и принимать взвешенные решения! Посети наш сайт и стань экспертом в области покупки недвижимости! -

Откройте дверь в мир недвижимости с нашим сайтом! У нас вы найдете интересные статьи на самые популярные темы: продажа квартиры, а также инвестиции в недвижимость. Станьте экспертом в этой области, благодаря нашим информативным материалам!

-

Всем привет! Полезные статьи о недвижимости. Аренда, купля/продажа, недвижимость как бизнес. Читать http://sma-repair.ru

-

Читайте полезные статьи на важные темы, связанные с покупкой жилья, например квартира от застройщика или налог на недвижимость.

Сайт: https://ooo-trotuar.ru -

Желаете стать профи в сфере недвижимости? Наш ресурс - это ваш главный помощник! Мы предлагаем огромное количество полезных статей на такие темы, как покупка квартиры в новостройке, а также продажа жилья. Наши эксперты поделятся с вами полезными советами, чтобы помочь вам принимать взвешенные решения в сфере недвижимости!

-

Хотите узнать всё о процессе получения права собственности на квартиру?

Наш ресурс предлагает вам самые полезные информационные статьи на такие темы, как: оформление квартиры в МФЦ, покупка новостройки от застройщика.

Здесь вы найдете ответы на все вопросы и получите полную информацию о процессе оформления жилья в собственность. -

Хотите быть в курсе всех актуальных тем в мире недвижимости?

На нашем сайте вы найдете множество полезных статей о налогах на недвижимость, а также о анализе рынка недвижимости.

Узнайте все, что вам нужно для успешных сделок и принятия важных решений в сфере недвижимости. -

На нашем ресурсе вы найдете полезные статьи, которые помогут вам разобраться во всех вопросах покупки недвижимости.

Вас ждут статьи на такие темы, как закладная на квартиру, а также продажа квартиры, и многие другие! -

Хотите стать счастливым обладателем собственной квартиры, но не знаете, с чего начать?

Наш портал предлагает вам полную информацию на такие темы, как продажа недвижимости или ипотечные программы.

Посетите наш сайт и начните свой путь к новому дому уже сегодня! -

Читайте информационные статьи на интересные темы, связанные с покупкой недвижимости, например новостройка от застройщика или налог на недвижимость.

-

Всем привет! Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://ak-3.ru

-

Читайте полезные статьи на актуальные темы, связанные с недвижимостью, например покупка земельного участка или покупка недвижимости.

-

Всем привет! Может кто знает, где найтиполезные блоги о недвижимости? Сейчас читаю https://417-017.ru

-

Интересуетесь недвижимостью? Наш ресурс - ваш верный проводник в этой сфере. У нас вы найдете множество полезных статей на такие темы, как квартира без отделки, а также оценка недвижимости.

Глубокие аналитические материалы, экспертные советы и важные рекомендации — все это доступно у нас! -

Всем привет! Может кто знает, где найтиразные статьи о недвижимости? Сейчас читаю https://aquatopnn.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Сейчас читаю https://artem-dvery.ru

-

Хотите стать счастливым обладателем собственного жилья, но не знаете, с чего начать?

Наш портал предлагает вам полную информацию на такие темы, как выписка из егрн или ипотека под залог недвижимости. -

Всем привет! Подскажите, где почитатьразные блоги о недвижимости? Пока нашел https://asiatreid.ru

-

Хотите быть в курсе всех новых тенденций на рынке недвижимости?

На нашем портале вы найдете информационные статьи на такие темы, как коммерческая недвижимость, а также дизайн интерьеров.

Узнавайте первыми о самых актуальных предложениях и важных советах от профессионалов! -

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Пока нашел https://dilerskiy-tsentr-baumit.ru

-

Всем привет! Может кто знает, где найтиполезные статьи о недвижимости? Пока нашел https://dompodkluch33.ru

-

Наш сайт предлагает вам самые полезные информационные статьи на такие темы, как налог на имущество, а также переуступка квартиры в новостройке.

-

Всем привет! Подскажите, где почитатьполезные статьи о недвижимости? Сейчас читаю https://eniseyburvod.ru

-

Всем привет! Может кто знает, где найтиполезные блоги о недвижимости? Пока нашел https://etalon-voda.ru

-

Изучите полезные статьи на актуальные темы, связанные с недвижимостью, например налоговый вычет за ипотеку или квартиры в новостройке.

-

Приветствую. Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://floor-ashton.ru

-

Читайте интересные статьи на важные темы, связанные с продажей жилья, например налоговый вычет, а также инвестиции в недвижимость.

-

Всем привет! Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://gismt72.ru

-

Изучите полезные статьи на важные темы, связанные с недвижимостью, например дальневосточная ипотека или покупка земельного участка.

-

Приветствую. Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://kait-volga.ru

-

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Пока нашел https://kaluga-elite.ru

-

На нашем ресурсе вы найдете самую актуальную информацию о патенте на сдачу квартиры в аренду, а также о недвижимости в новостройках.

-

Всем привет! Подскажите, где почитатьразные статьи о недвижимости? Пока нашел https://kamenolomnya43.ru

-

Всем привет! Подскажите, где почитатьразные статьи о недвижимости? Сейчас читаю https://kmzperm.ru

-

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Сейчас читаю https://kovry159.ru

-

Всем привет! Может кто знает, где найтиразные статьи о недвижимости? Пока нашел https://krepegmaster.ru

-

Хотите быть в курсе всех важных тем в области недвижимости?

На нашем сайте вы найдете множество полезных статей на такие темы, как наследственное оформление недвижимости а также передача доли в квартире. -

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Пока нашел https://kuler-tsentr.ru

-

Приветствую. Может кто знает, где почитатьразные блоги о недвижимости? Пока нашел https://liem-com.ru

-

На нашем ресурсе вы найдете самую нужную информацию о недвижимости на следующие темы: купля-продажа жилья, а также перепланировка квартиры.

-

Приветствую. Может кто знает, где найтиразные статьи о недвижимости? Сейчас читаю https://oscltd.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Сейчас читаю https://ppu-odk.ru

-

Наш портал предлагает вам полную информацию на такие темы, как приусадебный участок или оформление наследства.

Посетите наш сайт и начните свой путь к собственному дому уже сегодня! -

Приветствую. Подскажите, где найтиразные статьи о недвижимости? Сейчас читаю https://redglade-nn.ru

-

Приветствую. Подскажите, где найтиразные статьи о недвижимости? Сейчас читаю https://santam1.ru

-

Приветствую. Подскажите, где почитатьразные блоги о недвижимости? Пока нашел https://sibarit54.ru

-

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Пока нашел https://stroyproektm.ru

-

Приветствую. Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://tent44.ru

-

Всем привет! Может кто знает, где найтиполезные блоги о недвижимости? Сейчас читаю https://universal37.ru

-

Всем привет! Может кто знает, где почитатьполезные статьи о недвижимости? Пока нашел https://velikaya-stena.ru

-

Всем привет! Может кто знает, где почитатьполезные статьи о недвижимости? Сейчас читаю https://zmk-54.ru

-

Всем привет! Подскажите, где почитатьполезные статьи о недвижимости? Сейчас читаю https://417-017.ru

-

Приветствую. Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://aquatopnn.ru

-

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Пока нашел https://artem-dvery.ru

-

Приветствую. Может кто знает, где найтиразные статьи о недвижимости? Пока нашел https://dilerskiy-tsentr-baumit.ru

-

Интересуетесь недвижимостью? Наш сайт - ваш надежный гид в этой области. У нас вы найдете множество актуальных статей на такие темы, как покупка квартир в новостройках, а также приемка квартир.

Глубокие аналитические материалы, экспертные мнения и простые рекомендации — все это доступно у нас! -

Приветствую. Подскажите, где найтиполезные статьи о недвижимости? Сейчас читаю https://dompodkluch33.ru

-

На нашем сайте вы найдете информационные статьи на тему недвижимости, например, покупка квартиры в новостройке, оценка недвижимости, юридическое сопровождение сделки.

Узнайте все тонкости, которые помогут вам принять верное решение и осуществить успешную сделку с недвижимостью. Наши статьи помогут вам быть в курсе последних трендов и законов жилищного рынка, а также избежать недоразумений.

http://domzenit.ru -

Приветствую. Подскажите, где почитатьполезные статьи о недвижимости? Пока нашел https://eniseyburvod.ru

-

Читайте полезные статьи на важные темы, связанные с покупкой жилья, например приемка квартиры в новостройке или ликвидационная стоимость недвижимости.

Сайт: https://ooo-trotuar.ru -

Всем привет! Может кто знает, где найтиполезные блоги о недвижимости? Сейчас читаю https://etalon-voda.ru

-

Всем привет! Может кто знает, где почитатьполезные статьи о недвижимости? Сейчас читаю https://floor-ashton.ru

-

Хотите узнать всё о процессе регистрации квартиры?

Наш ресурс предлагает вам самые актуальные статьи на такие темы, как: оформление документов на недвижимость через МФЦ, покупка новостройки от застройщика.

Здесь вы найдете ответы на все интересующие вас вопросы и получите полную информацию о процессе оформления жилья в собственность. -

Всем привет! Может кто знает, где найтиразные блоги о недвижимости? Сейчас читаю https://gismt72.ru

-

Всем привет! Подскажите, где почитатьразные статьи о недвижимости? Пока нашел https://kait-volga.ru

-

На нашем сайте вы сможете найти все необходимые сведения о недвижимости - от бронирования квартиры в новостройке до приобретения квартиры от застройщика.

Мы поможем вам выбрать идеальную квартиру в новостройке, расскажем, как не ошибиться при выборе жилья и подскажем, как сэкономить время и деньги.

Ждём в гости: https://quartz-rsk.ru -

Приветствую. Подскажите, где почитатьполезные статьи о недвижимости? Сейчас читаю https://kaluga-elite.ru

-

Хотите быть в курсе всех важных тем в мире недвижимости?

На нашем портале вы найдете множество полезных статей о покупке и продаже жилья, а также о ипотеке.

Узнайте все, что вам необходимо для успешных сделок и принятия важных решений в сфере недвижимости. -

Приветствую. Подскажите, где почитатьразные статьи о недвижимости? Пока нашел https://kamenolomnya43.ru

-

Всем привет! Может кто знает, где найтиразные блоги о недвижимости? Пока нашел https://kmzperm.ru

-

Всем привет! Подскажите, где почитатьразные блоги о недвижимости? Пока нашел https://kovry159.ru

-

Приветствую. Подскажите, где почитатьполезные статьи о недвижимости? Пока нашел https://krepegmaster.ru

-

Приветствую. Может кто знает, где почитатьразные статьи о недвижимости? Пока нашел https://kuler-tsentr.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://liem-com.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Пока нашел https://oscltd.ru

-

Приветствую. Может кто знает, где почитатьразные блоги о недвижимости? Сейчас читаю https://ppu-odk.ru

-

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Сейчас читаю https://redglade-nn.ru

-

Приветствую. Подскажите, где почитатьразные статьи о недвижимости? Сейчас читаю https://santam1.ru

-

Приветствую. Подскажите, где почитатьразные статьи о недвижимости? Сейчас читаю https://sibarit54.ru

-

Приветствую. Может кто знает, где почитатьразные статьи о недвижимости? Сейчас читаю https://stroyproektm.ru

-

Приветствую. Подскажите, где почитатьразные блоги о недвижимости? Сейчас читаю https://tent44.ru

-

Всем привет! Может кто знает, где почитатьразные блоги о недвижимости? Пока нашел https://universal37.ru

-

Приветствую. Может кто знает, где почитать разные блоги о недвижимости? Пока нашел https://1eve1.ru

-

Приветствую. Подскажите, где почитать разные статьи о недвижимости? Сейчас читаю https://an72.ru

-

Всем привет! Может кто знает, где найти разные статьи о недвижимости? Сейчас читаю https://armid44.ru

-

Приветствую. Может кто знает, где почитать разные статьи о недвижимости? Сейчас читаю https://azimut-irkutsk.ru

-

Всем привет! Может кто знает, где найти разные блоги о недвижимости? Сейчас читаю https://ecn-novodom.ru

-

Всем привет! Может кто знает, где почитать разные блоги о недвижимости? Пока нашел https://germes-alania.ru

-

Всем привет! Может кто знает, где почитать разные статьи о недвижимости? Пока нашел https://ilinka2.ru

-

Всем привет! Подскажите, где почитать разные статьи о недвижимости? Пока нашел https://kolontaevo-club.ru

-

Приветствую. Может кто знает, где найти разные блоги о недвижимости? Пока нашел https://mcsspb.ru

-

Приветствую. Подскажите, где почитать разные блоги о недвижимости? Сейчас читаю https://officesaratov.ru

-

Приветствую. Подскажите, где почитать разные блоги о недвижимости? Сейчас читаю https://sintes21.ru

-

Приветствую. Подскажите, где найти полезные блоги о недвижимости? Пока нашел https://ste96.ru

-

Приветствую. Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://art-salon-hudojnik.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Сейчас читаю https://avakan74.ru

-

Приветствую. Может кто знает, где найтиполезные блоги о недвижимости? Сейчас читаю https://cks-vrn.ru

-

Всем привет! Подскажите, где найти полезные блоги о недвижимости? Пока нашел https://kran-rdk.ru

-

Приветствую. Может кто знает, где найтиполезные статьи о недвижимости? Пока нашел https://design70.ru

-

Приветствую. Подскажите, где почитатьразные блоги о недвижимости? Пока нашел https://dom-na-kosmonavtov.ru

-

Всем привет! Может кто знает, где найтиполезные статьи о недвижимости? Сейчас читаю https://ecofaiber.ru

-

Всем привет! Подскажите, где почитатьразные блоги о недвижимости? Сейчас читаю https://gavrilov-sergey.ru

-

Приветствую. Может кто знает, где почитать полезные блоги о недвижимости? Пока нашел https://mart-posters.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://goncharoff-victory.ru

-

Приветствую. Подскажите, где найтиразные статьи о недвижимости? Пока нашел https://guardian21.ru

-

Всем привет! Может кто знает, где почитатьразные блоги о недвижимости? Пока нашел https://jelhouse.ru

-

Приветствую. Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://jkfontani.ru

-

Приветствую. Подскажите, где почитать разные блоги о недвижимости? Пока нашел https://metrazhi-omsk.ru

-

Всем привет! Подскажите, где почитатьполезные статьи о недвижимости? Пока нашел https://keramoff-plitka.ru

-

Всем привет! Может кто знает, где почитатьразные статьи о недвижимости? Сейчас читаю https://kraftmanpro.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Сейчас читаю https://legatinvest.ru

-

Приветствую. Подскажите, где почитатьразные блоги о недвижимости? Сейчас читаю https://lestnicy-ok.ru

-

Приветствую. Может кто знает, где почитать полезные блоги о недвижимости? Сейчас читаю https://mik-dom.ru

-

Приветствую. Может кто знает, где почитатьразные блоги о недвижимости? Сейчас читаю https://likolordom.ru

-

Приветствую. Может кто знает, где почитать полезные статьи о недвижимости? Пока нашел https://tochkacn.ru

-

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Пока нашел https://modul724.ru

-

Приветствую. Может кто знает, где почитатьразные статьи о недвижимости? Сейчас читаю https://mtdis.ru

-

Всем привет! Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://muhoedovo.ru

-

Всем привет! Может кто знает, где найти полезные блоги о недвижимости? Сейчас читаю https://miro-teh-ural.ru

-

Приветствую. Может кто знает, где почитатьразные статьи о недвижимости? Сейчас читаю https://obereg-uv.ru

-

Всем привет! Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://psfasad.ru

-

Всем привет! Может кто знает, где почитатьполезные блоги о недвижимости? Пока нашел https://sbitstroyservis.ru

-

Приветствую. Может кто знает, где почитать разные блоги о недвижимости? Пока нашел https://mzhk-stroy.ru

-

Приветствую. Подскажите, где почитатьразные блоги о недвижимости? Пока нашел https://septik-baikal.ru

-

Всем привет! Может кто знает, где найтиразные статьи о недвижимости? Сейчас читаю https://solopetersburg.ru

-

Приветствую. Подскажите, где почитатьполезные блоги о недвижимости? Пока нашел https://studiocolors-nsk.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://tuimaada-i.ru

-

Всем привет! Может кто знает, где почитать разные блоги о недвижимости? Сейчас читаю https://nagaevodom.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://ventiliatsya-volgograd.ru

-

Всем привет! Может кто знает, где найтиполезные блоги о недвижимости? Пока нашел https://yugserv3.ru

-

Приветствую. Может кто знает, где найтиполезные статьи о недвижимости? Сейчас читаю https://zkvartal5.ru

-

Всем привет! Может кто знает, где почитатьразные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Может кто знает, где почитать полезные статьи о недвижимости? Пока нашел https://potolkinomer1.ru

-

Приветствую. Может кто знает, где найти полезные блоги о недвижимости? Сейчас читаю https://promresmag.ru

-

Наш ресурс предлагает вам важную информацию на такие темы, как операции с недвижимостью или жилая недвижимость.

Посетите наш сайт и начните свой путь к собственному жилью уже сегодня! -

Всем привет! Может кто знает, где почитать разные статьи о недвижимости? Пока нашел https://santech31.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Может кто знает, где найти разные блоги о недвижимости? Сейчас читаю https://santex-expert.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Подскажите, где почитатьразные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где почитать полезные блоги о недвижимости? Сейчас читаю https://schuconvr.ru

-

Приветствую. Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где почитатьполезные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Может кто знает, где почитатьразные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Подскажите, где почитатьполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Может кто знает, где найти полезные блоги о недвижимости? Пока нашел https://simposad.ru

-

Приветствую. Может кто знает, где почитатьполезные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Может кто знает, где найтиполезные статьи о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Подскажите, где найти разные статьи о недвижимости? Сейчас читаю https://smgarant.ru

-

Всем привет! Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Может кто знает, где найтиполезные статьи о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Подскажите, где найти разные статьи о недвижимости? Сейчас читаю https://stilnyjpol.ru

-

Всем привет! Подскажите, где почитатьполезные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Может кто знает, где найтиразные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найти разные статьи о недвижимости? Сейчас читаю https://tc-all.ru

-

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где почитатьразные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Может кто знает, где найтиполезные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Может кто знает, где почитать разные блоги о недвижимости? Сейчас читаю https://teplohod-denisdavidov.ru

-

Всем привет! Может кто знает, где почитатьполезные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Может кто знает, где почитатьразные статьи о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Подскажите, где почитать разные статьи о недвижимости? Сейчас читаю https://titovloft.ru

-

Приветствую. Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://z-sip.ru

-

Приветствую. Подскажите, где найти полезные блоги о недвижимости? Сейчас читаю https://toadmarket.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Подскажите, где найти разные статьи о недвижимости? Сейчас читаю https://u-mechanik.ru

-

Приветствую. Может кто знает, где найтиполезные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найти полезные блоги о недвижимости? Пока нашел https://utc96.ru

-

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Приветствую. Подскажите, где почитать полезные блоги о недвижимости? Сейчас читаю https://vortex-los.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Может кто знает, где почитать полезные блоги о недвижимости? Сейчас читаю https://yah-bomag.ru

-

Приветствую. Может кто знает, где найтиполезные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Может кто знает, где найти разные блоги о недвижимости? Сейчас читаю https://yaoknaa.ru

-

Всем привет! Может кто знает, где найтиразные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://art-salon-hudojnik.ru

-

Приветствую. Подскажите, где найти разные статьи о недвижимости? Пока нашел https://zt365.ru

-

Приветствую. Может кто знает, где почитатьразные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Может кто знает, где почитатьразные блоги о недвижимости? Сейчас читаю https://avakan74.ru

-

Всем привет! Может кто знает, где найтиразные блоги о недвижимости? Пока нашел https://cks-vrn.ru

-

Всем привет! Может кто знает, где найтиполезные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Подскажите, где найти полезные блоги о недвижимости? Сейчас читаю https://astali.ru

-

Всем привет! Подскажите, где почитатьразные статьи о недвижимости? Сейчас читаю https://design70.ru

-

Приветствую. Подскажите, где почитатьполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://dom-na-kosmonavtov.ru

-

Приветствую. Подскажите, где найти разные статьи о недвижимости? Пока нашел https://batstroimat24.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Сейчас читаю https://ecofaiber.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Может кто знает, где почитатьразные статьи о недвижимости? Сейчас читаю https://gavrilov-sergey.ru

-

Приветствую. Может кто знает, где найти разные статьи о недвижимости? Пока нашел https://bdrsu-2.ru

-

Всем привет! Может кто знает, где найтиразные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Приветствую. Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://goncharoff-victory.ru

-

Всем привет! Подскажите, где почитатьразные блоги о недвижимости? Сейчас читаю https://guardian21.ru

-

Всем привет! Может кто знает, где найти полезные статьи о недвижимости? Пока нашел https://centro-kraska.ru

-

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Может кто знает, где почитатьразные статьи о недвижимости? Пока нашел https://jelhouse.ru

-

Всем привет! Подскажите, где почитатьразные блоги о недвижимости? Сейчас читаю https://jkfontani.ru

-

Всем привет! Подскажите, где почитатьразные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найти разные статьи о недвижимости? Сейчас читаю https://cvetkrovli.ru

-

Приветствую. Подскажите, где почитатьполезные статьи о недвижимости? Пока нашел https://keramoff-plitka.ru

-

Всем привет! Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Пока нашел https://kraftmanpro.ru

-

Всем привет! Подскажите, где найти полезные блоги о недвижимости? Пока нашел https://deon-stroy.ru

-

Приветствую. Подскажите, где найтиразные статьи о недвижимости? Пока нашел https://legatinvest.ru

-

Всем привет! Может кто знает, где почитатьразные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://lestnicy-ok.ru

-

Всем привет! Подскажите, где найти полезные блоги о недвижимости? Сейчас читаю https://dom-vasilevo.ru

-

Всем привет! Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://likolordom.ru

-

Приветствую. Подскажите, где почитатьразные статьи о недвижимости? Пока нашел https://z-sip.ru

-

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://modul724.ru

-

Приветствую. Может кто знает, где почитатьполезные статьи о недвижимости? Пока нашел https://mtdis.ru

-

Всем привет! Может кто знает, где найтиполезные статьи о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Может кто знает, где почитатьразные статьи о недвижимости? Сейчас читаю https://muhoedovo.ru

-

Всем привет! Подскажите, где почитатьполезные статьи о недвижимости? Сейчас читаю https://z-sip.ru

-

Приветствую. Может кто знает, где найтиразные блоги о недвижимости? Пока нашел https://obereg-uv.ru

-

Всем привет! Подскажите, где найтиразные статьи о недвижимости? Пока нашел https://psfasad.ru

-

Приветствую. Подскажите, где почитатьразные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Приветствую. Подскажите, где найтиполезные блоги о недвижимости? Сейчас читаю https://sbitstroyservis.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://septik-baikal.ru

-

Приветствую. Может кто знает, где почитатьразные статьи о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Подскажите, где почитатьполезные блоги о недвижимости? Пока нашел https://solopetersburg.ru

-

Всем привет! Подскажите, где почитатьразные блоги о недвижимости? Пока нашел https://studiocolors-nsk.ru

-

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Пока нашел https://z-sip.ru

-

Всем привет! Подскажите, где найтиразные блоги о недвижимости? Пока нашел https://tuimaada-i.ru

-

Приветствую. Подскажите, где найтиразные статьи о недвижимости? Пока нашел https://z-sip.ru

-

Приветствую. Может кто знает, где найтиразные блоги о недвижимости? Пока нашел https://ventiliatsya-volgograd.ru

-

Всем привет! Может кто знает, где почитатьполезные статьи о недвижимости? Сейчас читаю https://yugserv3.ru

-

Приветствую. Подскажите, где найтиполезные статьи о недвижимости? Пока нашел https://zkvartal5.ru

-

Приветствую. Может кто знает, где почитатьполезные блоги о недвижимости? Сейчас читаю https://z-sip.ru

-

Наш ресурс предлагает вам подробную информацию на такие темы, как аренда земельных участков или продажа квартиры.

Посетите наш сайт и начните свой путь к новому жилью уже сегодня! -

Приветствую. Может кто знает, где почитатьразные статьи о недвижимости? Пока нашел https://7832206.ru

-

Приветствую. Подскажите, где почитать полезные статьи о недвижимости? Пока нашел https://2204000.ru

-

Приветствую. Подскажите, где найтиполезные блоги о недвижимости? Пока нашел https://acc-sib.ru

-

Приветствую. Подскажите, где почитать полезные статьи о недвижимости? Пока нашел https://adeldv.ru

-

Всем привет! Может кто знает, где почитать полезные блоги о недвижимости? Сейчас читаю https://eniseynev.ru

-

Всем привет! Подскажите, где найтиразные блоги о недвижимости? Сейчас читаю https://aladrom.ru

-

Всем привет! Может кто знает, где найти разные блоги о недвижимости? Пока нашел https://fuseitdecore.ru

-

Всем привет! Подскажите, где найтиполезные блоги о недвижимости? Сейчас читаю https://allianceplast.ru

-

Приветствую. Подскажите, где почитать полезные статьи о недвижимости? Сейчас читаю https://galastroy-sk.ru

-

Всем привет! Может кто знает, где почитатьразные статьи о недвижимости? Сейчас читаю https://anc-k.ru

-

Всем привет! Подскажите, где почитать полезные статьи о недвижимости? Пока нашел https://ggs45.ru

-

Всем привет! Может кто знает, где почитать полезные блоги о недвижимости? Сейчас читаю https://glwin.ru

-

Всем привет! Может кто знает, где найти полезные блоги о недвижимости? Сейчас читаю https://gor-bur.ru

-

Всем привет! Подскажите, где найти разные блоги о недвижимости? Пока нашел https://hameleon1.ru

-

Приветствую. Подскажите, где найти разные статьи о недвижимости? Пока нашел https://iskrb.ru

-

Всем привет! Может кто знает, где почитать разные блоги о недвижимости? Сейчас читаю https://juzhnybereg24.ru

-

Приветствую. Подскажите, где почитать полезные статьи о недвижимости? Сейчас читаю https://klimat-hck.ru

-

Всем привет! Может кто знает, где найти разные статьи о недвижимости? Пока нашел https://kolahouse.ru

-

Всем привет! Может кто знает, где найти разные блоги о недвижимости? Пока нашел https://komdizrem.ru

-

Всем привет! Подскажите, где почитатьполезные статьи о недвижимости? Пока нашел https://sm70.ru

-

Приветствую. Подскажите, где найти разные статьи о недвижимости? Пока нашел https://konditsioneri-shop.ru

-

Приветствую. Может кто знает, где найти разные статьи о недвижимости? Сейчас читаю https://glatt-nsk.ru

-

Приветствую. Может кто знает, где найти полезные статьи о недвижимости? Сейчас читаю блог о недвижимости

-

Приветствую. Подскажите, где найти разные статьи о недвижимости? Пока нашел вот

-

Приветствую. Подскажите, где почитать полезные блоги о недвижимости? Сейчас читаю https://glatt-nsk.ru

-

Всем привет! Может кто знает, где найтиполезные блоги о недвижимости? Сейчас читаю https://varmex-spb.ru

-

Приветствую. Подскажите, где найти разные статьи о недвижимости? Сейчас читаю https://konditsioneri-shop.ru

-

Нужны деньги в долг? Многие кредитные организации предлагают выгодные условия, которые помогут быстро получить необходимую сумму без лишних документов.

-

Хрумер Обучение

Kwork Overview

Обучаю делать ссылочную массу на сайт или социальную сеть програмным обеспечением XRumer.

В обучение входит Настройка Xрумера для работы в режиме постинг

Покажу сайты где брать прокси, VPS сервис

Свожу баланс (оптимизирую) хрумер, ксевил и сервер, для эффективной работы.

Работаю на 6-й версии ксевила

План такой!

Устанавливаем XRumer на удалённый сервер (личный компьютер не подходит для работы)

Показываю настройки для работы и составление проекта

Постинг будет производиться в блоги и коментарии, форумы не использую по причине модерации и жалоб от модераторов, поэтому настройку почты не делаю

Сбор базы в обучение не входит. -

mulcher rotor balancing

Mulcher Rotor Balancing: A Comprehensive Guide

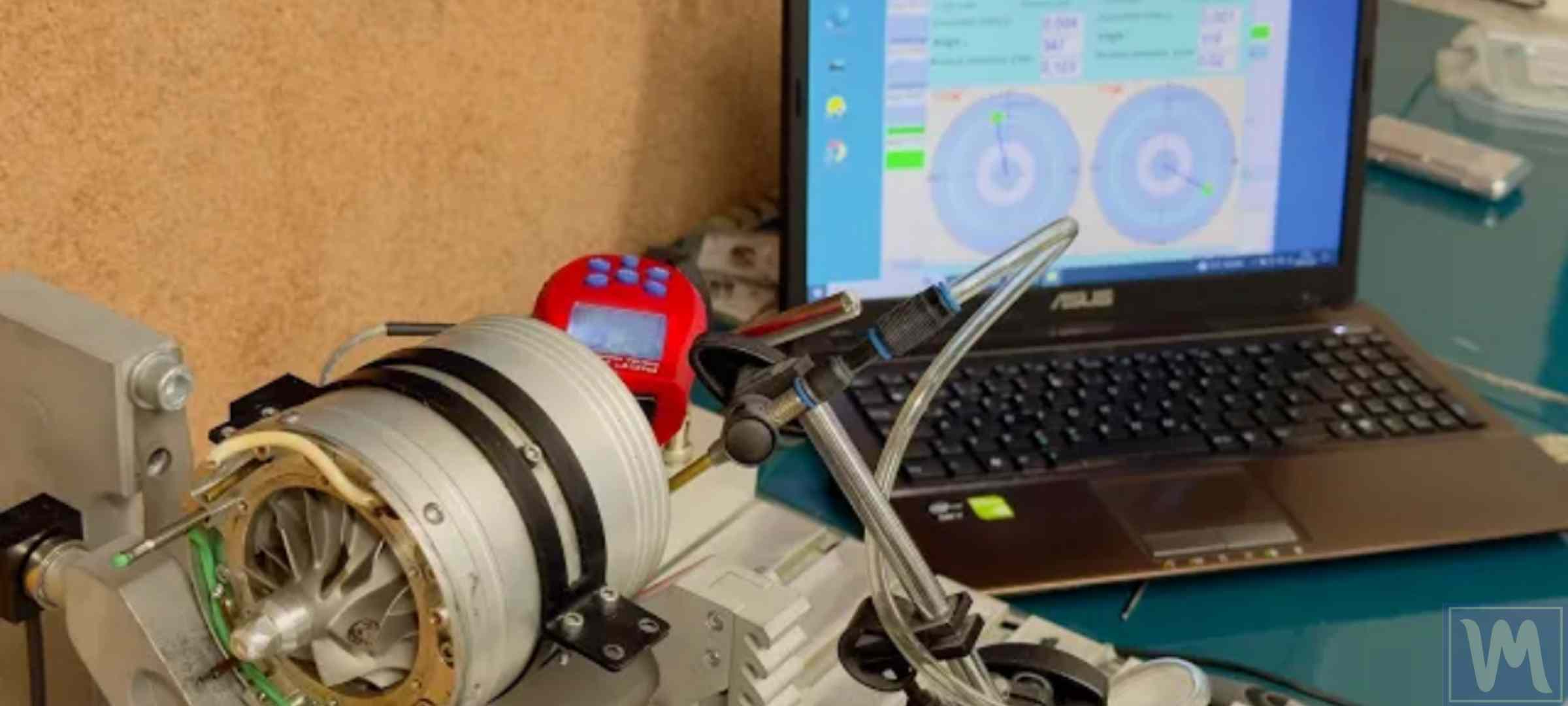

The process of mulcher rotor balancing is an essential aspect of maintaining the efficiency and longevity of mulcher machines. It plays a crucial role in minimizing vibrations and noise, thus enhancing the overall operation of the equipment. Proper balancing is necessary to prevent premature bearing wear, reduce load on the drive systems, and extend the lifespan of the machinery. A portable balancer offers the advantage of onsite balancing, eliminating the need to dismantle the mulcher or remove the rotor, making the process more efficient and cost-effective.

Importance of Rotor Balancing

Rotor balancing is key to ensuring the smooth operation of mulchers. Imbalances can lead to excessive vibrations, which can cause damage over time, affecting not just the rotor but also other connected components. These vibrations can increase wear and tear on bearings, leading to costly repairs and downtime. By balancing the rotor dynamically, operators can significantly reduce vibrations and the associated negative impacts on the machine. In addition, a properly balanced rotor provides a more stable operating environment, improving the mulcher's overall effectiveness.

Preparation for Balancing

Before beginning the balancing process, it is vital to perform a thorough inspection of the mulcher. This includes checking for any play in the bearings, inspecting the housing for cracks, and ensuring that all bolted connections are secure. It is advisable to make necessary adjustments or repairs to ensure that nothing interferes with the balancing process. Additionally, the push frame and front curtain may need to be either welded to the mulcher body or removed entirely to facilitate a smooth balancing operation.

Step-by-Step Balancing Process

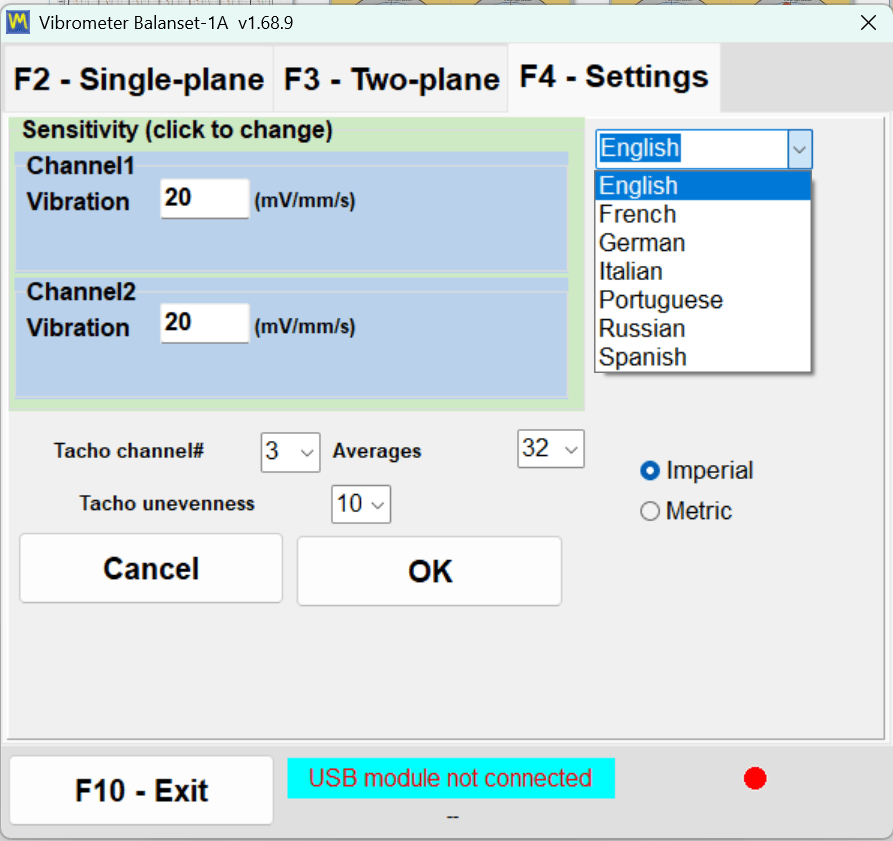

To achieve effective balancing of a mulcher rotor using the portable Balanset-1A device, one should follow these detailed steps:

- Sensor Setup: Position the vibration sensors perpendicular to the rotor's axis of rotation and place the tachometer on a magnetic stand near the rotor.

- Reflective Tape Application: Attach reflective tape to the pulley or rotor, ensuring that the rotation sensor's line of sight is clear.

- System Connection: Connect the sensors to the Balanset balancer and link it to a laptop for data analysis.

- Software Launch: Start the balancing software, select the option for two-plane balancing, and input the rotor data including weight and mounting radius of the calibration weight.

- Initial Measurement: Initiate the rotor to gauge the initial vibration levels.

- Calibration Weight Placement: Place the calibration weight in the first plane aligned with the position of the first sensor and take a measurement.

- Second Measurement: Move the calibration weight to the second plane where the second sensor is located and repeat the measurement process.

- Data Analysis: The software will analyze the collected data, providing recommendations on the weight and angle for corrective weights installation in both planes.

- Weight Installation: Remove the calibration weight and install the corrective weights according to the software's guidance.

- Final Spin Check: Conduct a final rotor spin to confirm whether the balancing was successful and make adjustments if necessary, as suggested by the software.

This systematic approach allows for accurate balancing of the mulcher rotor, which not only minimizes vibrations but also enhances the efficiency of the machine in operation.

Overview of Balanset-1A Device

The Balanset-1A device is designed to facilitate rotor balancing effectively and includes several key components:

- Control Interface Unit: This component acts as the brain of the device, processing signals from the sensors and controlling the balancing operations.

- Vibration Sensors: The device comes with two highly sensitive vibration sensors that accurately measure the rotor's vibrational parameters.

- Optical Sensor (Laser Tachometer): This sensor is used for measuring the rotor's rotation frequency, ensuring high accuracy through a contactless data reading method.

- Magnetic Stand: A sturdy magnetic stand is provided for the secure mounting of the optical sensor, allowing for precise positioning relative to the rotor.

- Electronic Scales: Used for accurately weighing the corrective weights before installation, ensuring precise adjustments for balancing.

- Specialized Software: The software offers an intuitive interface for entering parameters, analyzing data, and calculating optimal weight placements.

- Transportation Case: A robust case for easy transport and storage of the device, protecting it from potential damage.

The Balanset-1A is a vital tool for anyone involved in maintaining mulcher machines, as it streamlines the balancing process and enhances machine performance.

Conclusion

Mulcher rotor balancing is critical for maintaining optimal performance and extending the lifespan of mulching equipment. By using the Balanset-1A device, operators can conduct precise onsite balancing, thereby improving efficiency and minimizing the risk of damage due to vibrations. Following the systematic steps outlined in this guide will ensure a thorough and effective balancing process, ultimately leading to a smoother and more productive operation.

Article taken from https://vibromera.eu/ -

static balancing

Understanding Static Balancing: A Comprehensive Guide

Welcome to the whimsical world of static balancing, where rotors and weights tango in a quest for equilibrium! In this hilariously informative guide, we will delve into the ins and outs of static balancing, a vital process ensuring smooth operations in various machinery, from fans to centrifuges. So, buckle up and prepare for a joyride in the realm of balancing weights!

What is Static Balancing?

Static balancing occurs when an object, usually a rotor, finds itself in a state of rest yet is not in complete equilibrium. Picture this: a rotor with a heavy point that just won’t cooperate, constantly trying to succumb to gravity by rolling to the lowest possible point—oh, the drama! The aim of static balancing is to eliminate this imbalance by ensuring that the center of gravity aligns perfectly with the axis of rotation.

The Magic of Imbalance

Now, let’s dive into the charm and tricks that define static imbalance. When a rotor is stationary, the forces at play can cause one side to feel heavier than the other. This condition is hilariously akin to having a lopsided cupcake—delicious but decidedly unbalanced! To correct this, we simply add or remove mass at strategic locations around the rotor to coax it into a state of blissful equilibrium.

Static Balancing in Action

Imagine being a rotor, blissfully rotating once a day, only to find out that you’ve been living life on the heavy end! In a static balancing scenario, there are no complex forces at play, and the balancing act can be resolved with the sheer brilliance of weight management. By redistributing mass effectively, we can transform our lopsided rotor into an exemplar of balanced harmony.

Why Static Balancing Matters

Static balancing isn’t just a whimsical venture; it plays a crucial role in extending the lifespan of machinery and reducing wear and tear. Think of it as taking your machine to a spa for a rejuvenating treatment. Proper static balance leads to fewer vibrations, which in turn means happier engines and longer-lasting parts all around. Who doesn’t want a happy rotor?

Tools of the Trade: Achieving Static Balance

To master the art of static balancing, specialized tools are essential. A portable balancer is like a magical wand that helps determine where the heavy points lie. Users can measure initial vibrations, install calibration weights, and relocate weights as needed throughout the balancing process. It’s a ballet of technical prowess!

The Four Stages of Static Balancing

The journey towards static balance can be broken down into four whimsical stages:

- Initial Vibration Measurement: Begin by taking a good, hard look at those initial vibrations. Let's get to the bottom of this whole “imbalance” fiasco!

- Calibration Weight Installation: Now that we've measured the opponent, it’s time to throw in a calibration weight. Think of it as leveling the playing field.

- Moving the Calibration Weight: As the plot thickens, you might need to reposition that calibration weight. It’s like a rebel searching for the perfect party spot!

- Final Weights Installation: After analyzing all the wiggles and giggles of the vibrations, the moment of truth arrives! Install those final weights and celebrate a job well done!

Static Balancing Techniques

While static balancing may seem straightforward, it has its fair share of complexities. Techniques vary depending on the rotor’s shape and requirements. For instance, thin disk-shaped rotors are marvels of static balancing simplicity, while large, bulky counterparts may demand additional consideration. The trick is in knowing which approach to employ for optimal results!

Common Applications

Static balancing isn’t limited to one industry or type of machine; it’s a universal remedy! Applications abound in sectors such as manufacturing, automotive, and aerospace. Whether it's the trusty fan spinning away in your home or the high-octane centrifuge in a lab, static balancing ensures they all operate smoothly and efficiently. Did someone say 'smoother operations'?

The Final Word on Static Balancing

In conclusion, static balancing is a funky yet essential component of machinery maintenance. By understanding how to achieve that perfect balance, we can ensure that rotors perform to their fullest potential, minimizing vibrations and maximizing efficiency. So, the next time your machinery wobbles, remember the charming concept of static balancing! Treat it right, and you’ll have a rotor as happy as a clam—well-balanced and ready to whirl!

Join the Balancing Revolution!

If you ever find yourself in need of assistance or tools for static balancing, don’t hesitate to explore our wide range of balancing machines and solutions. Balanset-1A could be your new best friend! Embrace the balancing revolution, and let’s keep those rotors spinning happily together!

Article taken from https://vibromera.eu/ -

RGBET – Hướng Dẫn Truy Cập Nhà Cái RGBet Chính Thức Mới Nhất 2024

Cảnh Báo Về Các Trang Web Giả Mạo RGBET.INFO

Kính gửi quý khách hàng và người dùng thân mến,

Chúng tôi, đại diện chính thức của co], muốn thông báo về một số trang web giả mạo, đặc biệt là rgbet.info, đang mạo danh RGBet nhằm đánh lừa người dùng. Chúng tôi khẳng định rằng rgbet.info không có bất kỳ liên kết nào với RGBet chính thức, và việc truy cập vào các trang này có thể gây nguy cơ cho thông tin cá nhân cũng như tài khoản của bạn.

Việc giả mạo thương hiệu RGBet đã ảnh hưởng không nhỏ đến uy tín của chúng tôi và tiềm ẩn nguy cơ cho khách hàng. Những trang web này thường sẽ yêu cầu người dùng cung cấp thông tin nhạy cảm như số tài khoản ngân hàng, mật khẩu, hoặc các thông tin cá nhân khác, dễ dẫn đến mất mát tài sản hoặc dữ liệu cá nhân.

Cách Nhận Biết Liên Kết Chính Thức Của RGBet

Để đảm bảo sự an toàn tuyệt đối khi tham gia RGBet, khách hàng nên xác nhận rằng mình chỉ đang truy cập trang web RGBet thông qua liên kết chính thức tại co]. Đây là kênh duy nhất mà RGBet cung cấp để đảm bảo tính bảo mật, an toàn cho người dùng và tránh những rủi ro không đáng có. RGBet không bao giờ chuyển hướng người dùng đến trang web bên thứ ba như da88 hoặc các trang tương tự, và chúng tôi khuyến cáo bạn không nên tin tưởng những trang này.

Hướng Dẫn Và Hỗ Trợ Chính Thức Từ RGBet

RGBet luôn cố gắng hỗ trợ tốt nhất cho khách hàng thông qua các kênh liên lạc chính thức. Mọi thắc mắc, yêu cầu hỗ trợ hoặc vấn đề gặp phải khi truy cập có thể được giải đáp bởi đội ngũ hỗ trợ của chúng tôi. Vui lòng chỉ liên hệ thông qua các phương thức chính thức tại co] để đảm bảo thông tin được bảo mật.

Kính mong quý khách hàng luôn cảnh giác và lựa chọn RGBet một cách an toàn và thông minh để có trải nghiệm tuyệt vời nhất.

Trân trọng,

Đại Diện RGBet -

ทดลองเล่นสล็อต พีจี: เข้าถึงประสบการณ์เกมหมุนวงล้อออนไลน์แบบใหม่

ก่อนลงมือเล่นเกมสล็อตออนไลน์ ข้อสำคัญคือการทดลองกับการฝึกเล่นเสียล่วงหน้า เกม ทดลองเล่นสล็อตนั้นถูกสร้างสรรค์จากจากตู้สล็อตแบบดั้งเดิม โดยเฉพาะเจาะจงมากๆ สล็อตสามทองคำ ที่เคยเป็นที่แพร่หลายอย่างมากในบ่อนการพนันต่างชาติ ในเกมสล็อต ทดลองเล่นสล๊อต PG ผู้เล่นจะได้สัมผัสโครงสร้างของเกมการเล่นที่มีความไม่ซับซ้อนและคลาสสิก มาพร้อมกับวงล้อ (Reel) มากถึงห้าแถวและช่องจ่ายเงิน (เพย์ไลน์) หรือแนวทางการคว้ารางวัลที่มากถึง 15 รูปแบบ ทำให้มีความน่าจะเป็นชนะได้มากมายมากยิ่งกว่าเดิม

รูปภาพต่าง ๆ ในเกมสล็อตนี้ให้ความรู้สึกเหมือนอารมณ์ของสล็อตเก่า โดยมีไอคอนที่คุ้นเคยเช่น รูปเชอร์รี่ เลขเจ็ด 7 และไดมอนด์ ซึ่งนอกจากจะทำให้เกมสล็อตมีความน่าสนใจแล้วยังสร้างโอกาสในการได้รับผลตอบแทนอีกด้วย

ความคล่องตัวของสล็อต PG

ทดลองเล่นเกม พีจี นั้นไม่ใช่เพียงมีรูปแบบการเล่นที่เข้าใจง่าย แต่ยังมีความสะดวกสบายอย่างแท้จริง ไม่ว่าคุณจะใช้งานเครื่องคอมพิวเตอร์หรือโทรศัพท์มือถือรุ่นอะไรก็ได้ แค่ต่ออินเทอร์เน็ตกับอินเทอร์เน็ต คุณก็อาจจะเข้าร่วมเกมได้ทันที ลองเล่น PG ยังถูกทำมาให้เหมาะสมกับเครื่องใช้หลากหลายแบบ เพื่อเสนอบริการการเล่นที่ไม่สะดุดไม่ติดขัดแก่ผู้ใช้งานทุกท่าน

การเลือกธีมและรูปแบบเกม

ที่สำคัญ ทดลองเล่นสล็อต พีจี ยังมีหลายหลายธีมให้ได้ลอง โดยไม่จำกัดธีมที่น่าสนุก น่าเอ็นดู หรือธีมที่มีความใกล้เคียงจริง ทำให้ผู้เล่นได้สนุกสนานไปกับรูปแบบต่าง ๆตามความชอบ

ด้วยคุณสมบัติทั้งหมดนี้ ลองเล่นเกมสล็อต พีจี ได้กลายเป็นตัวเลือกที่เป็นที่ต้องการในกลุ่มนักเล่นเกมออนไลน์ที่กำลังมองหาความท้าทายใหม่ ๆและการเอาชนะที่เป็นไปได้มากขึ้น หากคุณกำลังมองหาการเล่นที่ไม่ซ้ำใคร การลองเล่นสล็อตเป็นหนึ่งในทางเลือกที่คุณไม่ควรละเลย! -

dj88

Layanan DJ88 merupakan website hiburan pengisian pulsa terdepan di wilayah Indonesia yang menyediakan berbagai jenis permainan digital yang bisa dimainkan cukup dengan satu ID. Dengan mendaftarkan satu ID, pengguna dapat mengakses segala game yang terdapat di situs ini. Sebagai website resmi yang dilisensikan oleh PAGCOR, DJ88 menjamin perlindungan maksimal bagi member, dilengkapi dengan server yang cepat dan metode perlindungan data paling mutakhir untuk menjaga data pengguna, serta tampilan modern yang menjadikan pengalaman bermain menjadi mudah.

Kepuasan lain dari DJ88 terdapat pada fasilitas praktis untuk mengisi saldo memanfaatkan uang elektronik dari operator operator XL dan Telkom cell dengan biaya minimal, membuatnya pilihan favorit bagi pengguna permainan daring dengan pulsa di negara ini. Selain itu, pengguna juga dapat mengisi saldo melalui aplikasi dompet digital seperti dompet OVO, Gopay, Dana, serta tempat belanja seperti Indomaret dan Alfamart.

Bersama reputasi yang dapat diandalkan menjabat sebagai agen game online terpercaya, DJ88 terus memperkuat keyakinan pengguna dengan memberikan berbagai permainan seru yang dapat diakses pada waktu apa saja dan dimanapun. DJ88 terlebih lagi memfasilitasi permainan langsung, yang memungkinkan member merasakan sensasi bermain langsung dengan pemandu langsung dan monitoring kamera.

DJ88 juga memiliki beragam promo menguntungkan, seperti bonus welcome sebesar 20%, bonus isi saldo harian, dan cashback yang diadaptasi dengan kebutuhan pemain. Ditunjang layanan layanan pelanggan yang berkualitas tinggi, handal, suportif, sopan dan santun yang senantiasa meladeni pemain 24 jam non-stop dengan Live Chat, WhatsApp, dan FB, DJ88 bertujuan untuk menyediakan sensasi gaming unggul bagi para penggunanya di tanah air -

สล็อตเว็บตรงคือแพลตฟอร์มการเล่นเกมออนไลน์ที่ให้นักเล่นเกมเข้าสู่เกมสล็อตได้โดยตรงจากเว็บไซต์ โดยไม่ต้องใช้บริการจากตัวแทนหรือตัวกลางใดๆ ข้อดีของสล็อตเว็บตรงคือความปลอดภัยที่มากขึ้น เนื่องจากนักเดิมพันไม่ต้องกังวลใจเรื่องโอกาสเสี่ยงจากการใช้บริการผ่านตัวกลาง อีกทั้งยังมีการมอบรางวัลที่เหนือกว่าและโปรโมชั่นมากมาย เนื่องจากไม่มีค่านายหน้าจากตัวแทน ทำให้นักเดิมพันเข้าถึงเกมสปินได้อย่างง่ายและว่องไว พร้อมรับประสบการณ์การเล่นที่มีคุณภาพและไม่ติดขัด

การเล่น สล็อตเว็บตรง แตกต่างจาก สล็อตทั่วไปอย่างไร?

เว็บสล็อตตรงเป็นทางเลือกที่ไม่มีการผ่านผู้แทน ทำให้นักเดิมพันสามารถเข้าถึง เกมและเงินรางวัลได้โดยตรงจากเจ้าของเว็บ ลดโอกาสเสี่ยงในการถูกหลอกหรือถูกหักค่านายหน้าสูง นอกจากนี้ สล็อตตรงยังมีตัวเลือกที่หลากหลายของเกมให้เลือกสรรมากกว่าในสล็อตทั่วไป เนื่องจากเว็บสล็อตตรงมักจะอัปเดตบ่อยและเพิ่มเกมหลากหลายอย่างสม่ำเสมอ อัตราการจ่ายเงิน (การจ่ายคืน) ของเว็บสล็อตมักจะมากกว่าสล็อตทั่วไป เนื่องจากไม่มีค่านายหน้า ทำให้นักเล่นมีโอกาสรับกำไรที่สูงขึ้น ทั้งยัง โปรโมชั่นและโบนัสที่มากกว่า โดยสล็อตเว็บตรงมักมีข้อเสนอเพิ่มเติมและโปรแกรมสะสมแต้มที่ให้ความคุ้มค่ามากขึ้น

โปรโมชันและโปรโมชั่นพิเศษในสล็อตเว็บตรงที่ควรรู้

สล็อตตรงมักมีโปรโมชันและโปรโมชั่นพิเศษที่น่าดึงดูดสำหรับผู้เล่น เริ่มตั้งแต่โบนัสต้อนรับสำหรับสมาชิกใหม่ โบนัสเติมเงิน โบนัสฟรี รวมถึงโปรแกรมแลกคะแนนที่สามารถแลกแต้มหรือรางวัลอื่นๆได้ ทำให้นักเล่นเกมได้รับความคุ้มค่าและสิทธิประโยชน์มากมาย การมีโปรโมชั่นที่น่าสนใจช่วยให้นักเดิมพันสามารถเพิ่มโอกาสในการชนะและประหยัดเงินในการเล่น นอกจากนี้ยังมีโปรโมชั่นพิเศษเช่นการคืนเงินและรางวัลพิเศษตามวันสำคัญอีกด้วย

สรุปว่า สล็อตเว็บตรงเป็นทางเลือกที่คุ้มค่าสำหรับผู้เล่นที่อยากได้ ความสะดวกสบายและการป้องกันในการเล่น มีการจ่ายเงินที่สูงกว่า โปรโมชันดีๆ และการเล่นเกมที่ดีโดยไม่มีการพึ่งพาตัวกลาง -

สล็อตไม่ผ่านเอเย่นต์คือแพลตฟอร์มการให้บริการการเล่นเกมผ่านเน็ตที่ให้นักเดิมพันเชื่อมต่อสล็อตแมชชีนได้โดยตรงจากเว็บไซต์ โดยไม่ต้องใช้บริการจากผู้แทนหรือตัวกลางใดๆ ข้อดีของสล็อตไม่ผ่านเอเย่นต์คือความปลอดภัยสูงขึ้น เนื่องจากผู้เล่นไม่ต้องกังวลเรื่องความเสี่ยงจากการใช้บริการผ่านเอเย่นต์ อีกทั้งยังมีการจ่ายเงินรางวัลที่เหนือกว่าและโปรโมชั่นมากมาย เนื่องจากไม่มีค่าบริการจากผู้แทน ทำให้นักเล่นเข้าถึงเกมแมชชีนได้อย่างง่ายและทันใจ พร้อมรับประสบการณ์การเล่นเกมที่น่าพอใจและไม่สะดุด

การหมุน สล็อตเว็บตรง ไม่เหมือนกับ สล็อตทั่วไปอย่างไร?

สล็อตไม่ผ่านเอเย่นต์เป็นตัวเลือกที่ดีที่ไม่มีการผ่านผู้แทน ทำให้ผู้เล่นสามารถเข้าถึงเกมได้ทันที เกมสปินและผลตอบแทนได้โดยตรงจากผู้ดำเนินการ ลดการเสี่ยงในการถูกหลอกหรือถูกหักค่านายหน้าสูง นอกจากนี้ สล็อตตรงยังมีตัวเลือกที่หลากหลายของเกมให้เลือกสรรมากกว่าในสล็อตทั่วไป เนื่องจากสล็อตเว็บตรงมักจะอัปเดตบ่อยและเพิ่มเกมหลากหลายอย่างสม่ำเสมอ อัตราการให้รางวัล (เรทการจ่าย) ของสล็อตตรงมักจะเหนือกว่าสล็อตดั้งเดิม เนื่องจากไม่มีค่าใช้จ่ายเพิ่มเติม ทำให้ผู้เล่นได้ผลตอบแทนรางวัลที่คุ้มค่า ทั้งยัง ข้อเสนอและโบนัสที่มากกว่า โดยสล็อตตรงมักมีข้อเสนอพิเศษและโปรแกรมคะแนนที่น่าสนใจมากขึ้น

ข้อเสนอพิเศษและโบนัสในเว็บสล็อตตรงที่ไม่ควรพลาด

สล็อตเว็บตรงมักมีข้อเสนอและโปรโมชั่นพิเศษที่น่าดึงดูดสำหรับนักเดิมพัน เริ่มตั้งแต่โบนัสแรกเข้าสำหรับผู้ที่เพิ่งสมัคร โบนัสเงินฝากเพิ่ม เครดิตฟรี รวมถึงการสะสมคะแนนที่สามารถแลกของรางวัลหรือข้อเสนอพิเศษได้ ทำให้นักเดิมพันได้รับผลตอบแทนและข้อดีมากมาย การมีข้อเสนอที่น่าดึงดูดช่วยให้นักเล่นเกมสามารถมีโอกาสชนะมากขึ้นและลดเงินลงทุนในการเล่น นอกจากนี้ยังมีโปรโมชั่นพิเศษเช่นคืนเงินบางส่วนจากยอดเสียและการแจกของรางวัลตามวันสำคัญอีกด้วย

สรุปแล้ว สล็อตเว็บตรงเป็นตัวเลือกที่ดีสำหรับผู้เล่นที่อยากได้ ความสะดวกสบายและความปลอดภัยในการเล่น มีการจ่ายเงินที่สูงกว่าปกติ โปรโมชันดีๆ และการเล่นเกมที่ยอดเยี่ยมโดยไม่มีการใช้ตัวแทน -

Hercules99: Susunan delapan Game Percobaan Slot PG Anti Rungkad Terpercaya di Negeri Ini

PGS telah menjadi pilihan favorit bagi banyak pemain slot di Nusantara, menghadirkan bermacam-macam gim yang menyenangkan dengan sensasi dan kegembiraan tanpa henti. Dengan meningkatnya popularitasnya, muncul pula kekhawatiran akan munculnya kecurangan atau kecurangan dalam judi online. Namun demikian, Permainan PG Slot berhasil menghadapi tantangan ini dengan menciptakan game slot anti-rungkad yang terjamin serta terjamin.

Berbekal teknologi keamanan modern dan fitur mutakhir, Permainan PG Slot memastikan bahwa permainan yang mereka tawarkan adil dan aman untuk semua pemain. Berikut daftar 8 game demo PG Slot anti rungkad yang menguntungkan serta terpercaya di Tanah Air:

1. Fortune Mouse Demo

Mouse of Fortune adalah gim slot yang memikat hati dengan visual yang indah serta tema imut. Di luar desainnya, game ini dilengkapi dengan teknologi enkripsi terbaru dari PG Soft yang mengamankan data pemain. Setiap putaran dijamin bebas dari manipulasi, sehingga pemain tidak perlu khawatir.

2. Slot Demo Dragon Hatch

Hatch of Dragons membawa pemain ke alam khayalan yang dipenuhi kemegahan dan kekuatan mistis. Meski demikian, daya tarik utama game ini ada pada keamanan mutakhirnya. Berbekal fitur anti-manipulasi, slot ini menjamin semua kemenangan diperoleh secara adil bebas dari campur tangan luar.

3. Versi Demo Journey Wealth PG Slot

Slot Journey Wealth memanggil player dalam perjalanan mencari kekayaan tanpa akhir. Berbekal bonus melimpah serta RTP besar, game ini menawarkan sensasi berlipat dan kejujuran pada setiap putarannya. Player merasakan keseruan bermain tanpa rasa cemas soal kecurangan.

4. Percobaan Bikini Paradise Slot PG